Engineered Precision, Proven Performance

Work From Home

Technical Strength

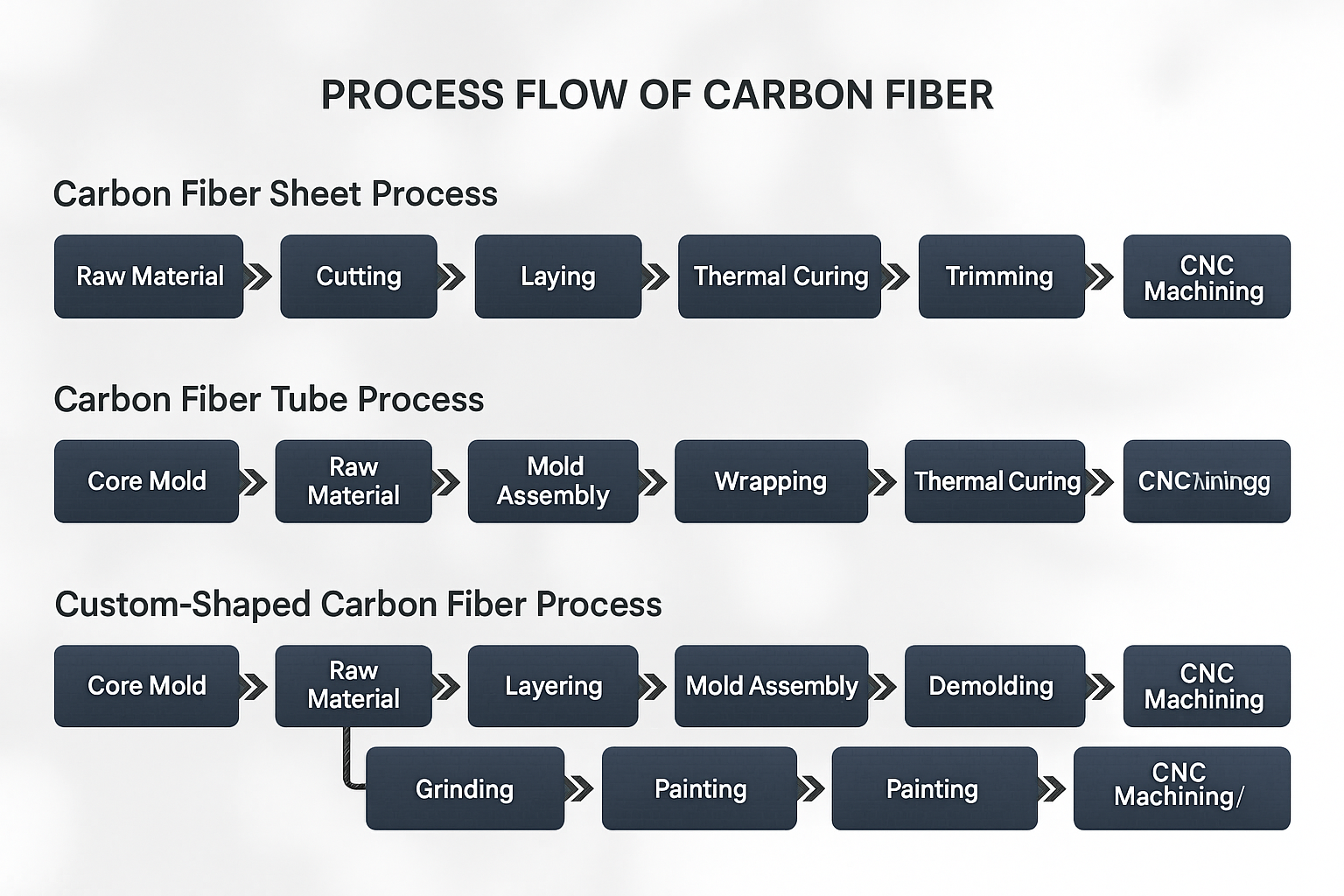

At Litian Carbon Fiber Tech, engineered precision drives every step of our production.

From material cutting to final machining, we maintain micron-level tolerances and strict quality benchmarks to ensure each carbon fiber component delivers exceptional strength, accuracy, and performance consistency.

Our workshops feature 5-axis CNC machining, compression molding lines, thermal curing systems, and precision inspection tools — enabling us to guarantee mechanical reliability, dimensional accuracy, and repeatable performance.

Whether you require small-batch prototyping or stable mass production, our integrated production capabilities and in-house engineering team guarantee that every product meets the highest demands of performance, design, and reliability.

Arcu erat turpis sed ullamcorper viverra amet, vel laoreet massa eu consequat ultricies accumsan, a magna morbi egestas augue proin sagittis, sit neque volutpat nisl elit mattis aenean eget eget facilisis massa duis volutpat purus diam nec at orci lacinia lectus id enim diam vivamus euismod nibh venenatis.

01

Raw Material Preparation

High-quality prepreg or dry carbon fiber fabrics are selected and cut precisely based on product specifications.

02

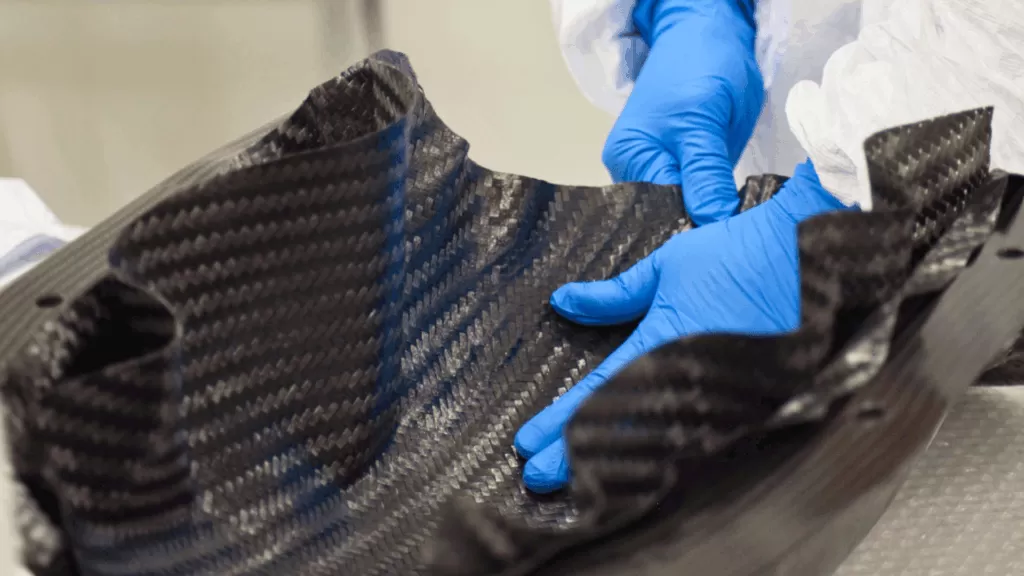

Fit the fabric

Carbon fiber layers are arranged manually or automatically according to the structural design, often with core materials for reinforcement.

03

Mold insertion

Carbon fiber layers are arranged manually or automatically according to the structural design, often with core materials for reinforcement.

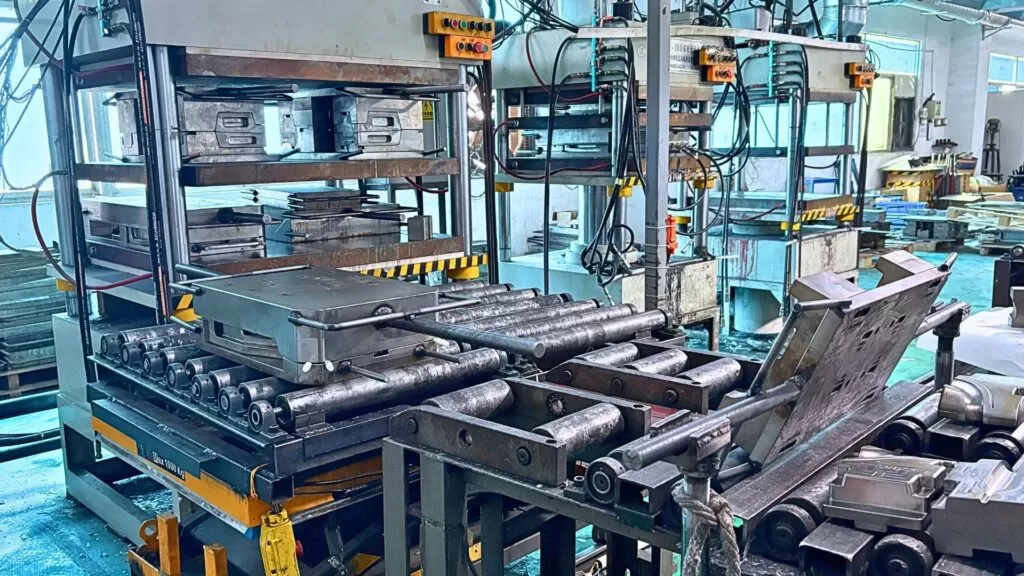

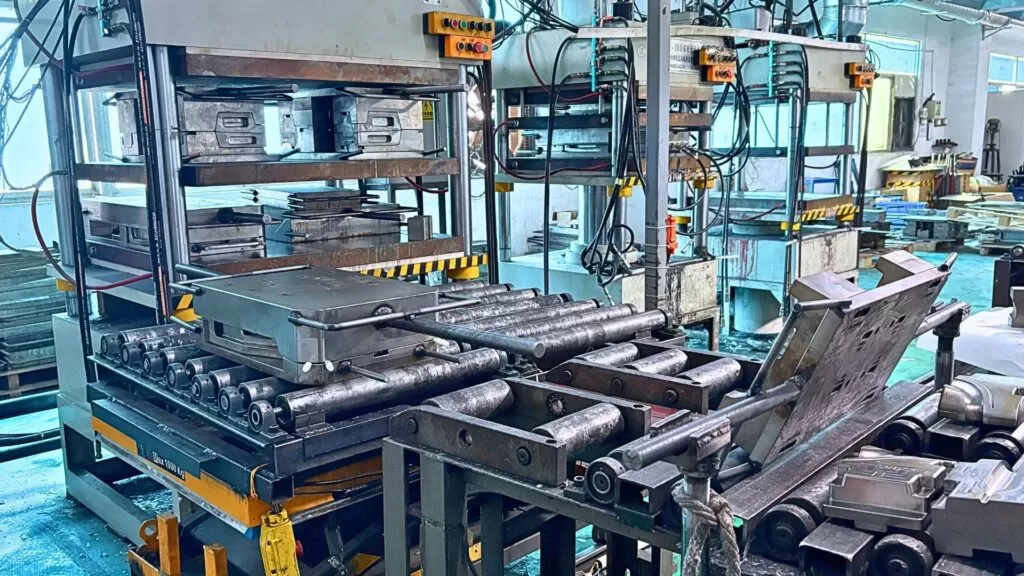

04

Hot pressing forming

Vacuum bagging is applied to eliminate air bubbles and ensure intimate contact between fiber layers and the mold.

05

Demolding & Trimming

Products are demolded and trimmed to remove excess material and ensure dimensional accuracy.

06

Surface Finishing

Sanding, painting, or clear coating improves the visual appeal and durability of the surface.

07

Inspection & Testing

Dimensional measurement and non-destructive testing verify product quality and structural integrity.

All tests follow ISO and industry-specific standards to validate strength, precision, and durability.

08

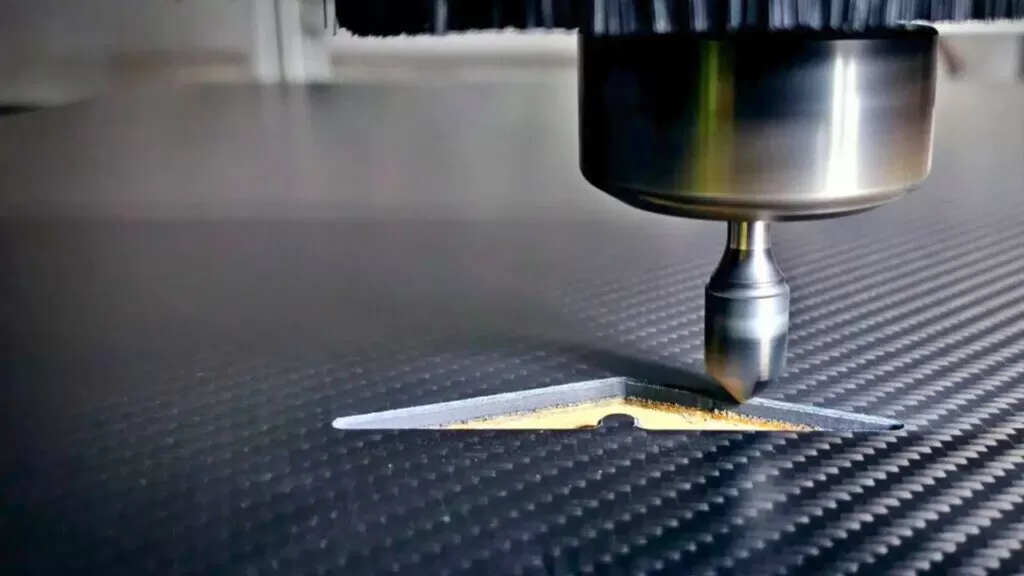

CNC machining

High-precision CNC machining for carbon fiber parts. Achieve complex shapes, tight tolerances, and smooth finishes—ideal for aerospace, automotive, and performance applications. Lightweight. Durable. Accurate.

Each machined part undergoes final tolerance checks to ensure zero deviation from digital models.

09

Curing

Thermal curing in molds or autoclaves allows full resin crosslinking and shape formation.

10

Assembly & Packaging

Final assembly, functional testing, and secure packaging prepare the product for delivery.